Common Questions Answered: Flat Mounting and Side Space

At Accuride, the experience of our customers is incredibly important to us. We want to make sure that you get the most out of our slides, which includes answering your questions about installation. In this article, we want to focus on two of the most common subjects that we get asked about: side space and flat mounting.

Side space

When installing any slide, overlooking the side space tolerance required can have an effect on the movement and durability of the final application. Side space refers to the distance between the outer element of the application and the inner element, which is the gap that the slide fits in. These elements are what the slide will be attached to, such as a cabinet and an internal drawer, for example, with the side space between the drawer and the cabinet.

This distance is critical if you intend to use a ball bearing slide and will vary depending on the slide you choose, although the principle will remain the same. The slide needs enough room to move freely and complete its function, but a careful balance must be struck between too much space and not enough. If there is not enough space for the slide to operate properly, the internal components will push against each other and cause friction, decreasing the ease of movement. Conversely, if there is too much space between the drawer and the cabinet, the slide members will be pulled apart and cause movement problems, leading to early product failure.

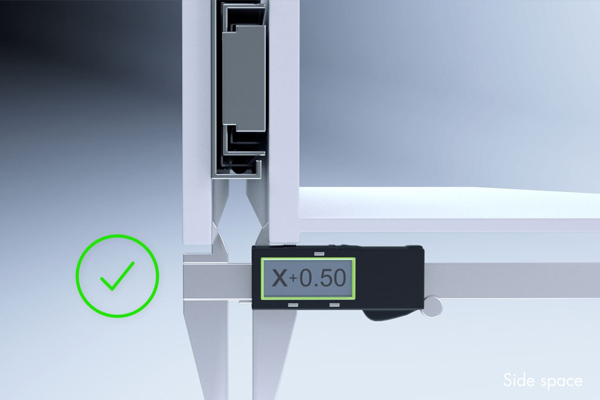

For optimal operation, we recommend that the side space is measured wider than the slide thickness by +0.2mm to +0.5mm. For example, the DZ3832 slide is 12.7mm thick. Therefore, the side space should be between 12.9mm and 13.2mm. It is also crucial to remember that the space must be consistent along the whole length of the slide. Ball bearing slides cannot absorb large gap deviations between the cabinet and the drawer, so consistency is key for longevity.

To calculate the side space required for your chosen slide before or during your project, please refer to the appropriate downloadable data sheet from the slide’s profile on our website. Additionally, the relevant 2D CAD file will provide the dimensional tolerances for each slide. If you need further guidance, contact us and one of our experts will assist you.

Flat mounting

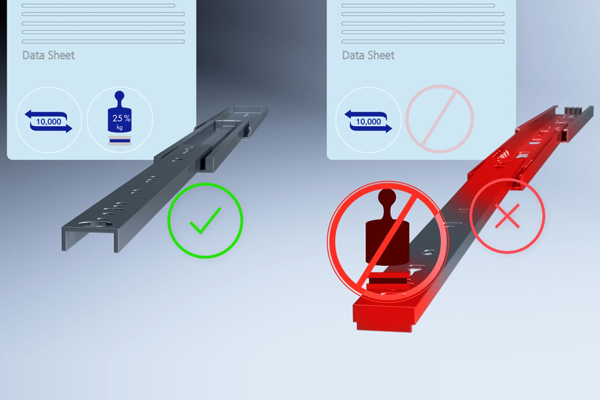

When a drawer slide is installed on the base of the drawer unit as opposed to the sides, this is known as horizontal mounting or flat mounting. While it may be your desired style to have a drawer supported from underneath by seemingly hidden slides, it is important to know not every design or model of slide is suitable for flat mounting. Look for the 25kg icon on the product datasheets to see if it is suitable for flat mounting.

Flat mounted slides cannot carry the full load rating the slide would be able to support when installed vertically (along the sides of the drawer). This is a crucial detail that must be taken into consideration when flat mounting is seen as an option. This is due to the fact that most slides will only be able to carry 25% of its total load capacity when flat mounted. This means, for example, a slide that is listed as having a load capacity of 40kg when mounted vertically will have its load capacity reduced to 10kg when mounted horizontally.

The suitability of the slides will depend on the style, as most telescopic slides are designed to be installed vertically. Linear slides such as the DZ1312 and DA0115RC perform better than other options when flat mounted as the moving member is supported on ball bearings at all times. The 0115RC, for example, uses a recirculating ball carriage, making it ideal for many applications in this orientation.

The DZ2601 or DZ2642 series, however, can’t be flat mounted due to the I-beam construction of the intermediate member. In a flat mount application, the outer member and ball retainer could easily pop out of the intermediate member even when the load weight is reduced to 25% of the load capacity.

We hope this article has helped to clarify some of the most common queries we often get from our customers, but if you still have any questions you can contact us today and speak to one of our friendly experts. Alternatively, you can download our What.How.When e-book from https://www.accuride-europe.com/en/resources/ebook

WATCH VIDEO: