Additive Manufacturing at Accuride

Over the last 40 years (yes, 40!), additive manufacturing has transformed the approach that engineers have to product development by bringing in digital flexibility and efficiency to manufacturing operations. Using computer aided design (CAD) software, additive manufacturing creates objects by directing hardware to deposit layer on layer of material in precise, geometric shapes. This allows more intricate designs to be carried out than would be possible through traditional techniques.

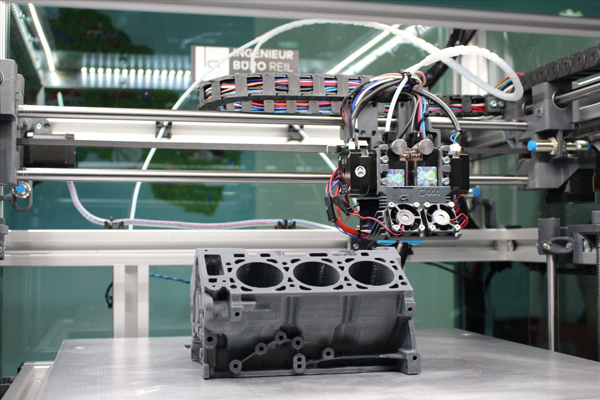

3D printing has come a long way since 1981 when Hideo Kodama of Nagoya Municipal Industrial Research Institute published his account of a functional rapid-prototyping system using photopolymers. 3D printers are now cheaper, opening up the possibilities to smaller companies and home inventors, and can now produce objects with greater accuracy. They aren’t even limited to only printing with acrylic-based plastic anymore, with gold rings, urban runabout vehicles, and even homes now being fully or partially constructed through 3D printing technology.

For our design engineers, 3D printing has made a huge difference in their approach to product development due to the relatively low price of getting prototype parts manufactured (rapid prototyping). While 3D printing itself can take longer than traditional machining or manufacturing techniques, there are usually no ancillary procedures or processes required, such as smelting metals, before producing the final product.

As additive manufacturing only uses the material required to create the object being printed, there is a huge reduction in waste material during rapid prototyping and production, which in turn can save costs for both the producer and the customer. The reduction of waste materials increases not only the efficiency of manufacture but additionally improves the environmental impact of production.

Rapid prototyping allows our design engineers more freedom to experiment with and test different solutions before committing to the final product. In this way, rapid prototyping through 3D printing has a positive effect on the performance of the end product, which in turn brings the benefits of the best possible solution to you, our customer.

In the same vein, we have made the optimised CAD drawings of our off-the-shelf products available to download from our site. This will allow product designers and engineers to save time during the creation of 3D CAD drawings for products that incorporate some of our most popular products. Our slide CAD drawings are available in 2D DXF, 3D IGS or 3D STEP formats and can be integrated into larger drawings within minutes due to their ‘fit, form and function’ optimisation. Just as our design engineers are able to experiment more, so will our customers be able to optimise their products by evaluating different telescopic slides during the design period.

With 3D printing and additive manufacturing becoming more accessible across the market, and speeds and accuracy improving all the time, do you think we will see product manufacturers start to shift their manufacturing processes? Do you think there will be a time when 3D printing takes over from traditional processes?

If you are interested in learning more about how our slides can be incorporated into your design projects, please contact us today.